An unusual period in history, the coronavirus pandemic has unleashed a series of unprecedented events affecting every industry.

Terminal operators face several challenges, striving to achieve higher productivity while reducing operational costs.

Staying on top of trends and accurate analysis is paramount now more than ever to manage uncertainty, change and continuously adapt to new and evolving market conditions.

Managers and entrepreneurs need to approach the business in a different way. Following the introduction of automation in the industry, not only specialised technical skills become increasingly important, but even new soft skills are vital for organisation resiliency and success, since automation requires change of mind-set, not mimicking.

Artificial Intelligence is brilliant at automating routine knowledge work and generating new insights from existing data: it will perform predictive analysis, preventive corrective actions, dynamically manage logistic flows and anticipate problems.

But AI cannot deduce the existence, or even the possibility of information it isn’t already aware of. AI cannot imagine radical new products and business models nor envision unimagined opportunities and achievements! We can say that systems are not (yet) self-sufficient and that results still rely on people interaction.

In the era of Digitalisation and Automation, technology enables us to measure process timestamps, delays, bottlenecks, and performances through KPIs, but on the other hand, the smart business expert will still take decisions, influence strategies, and motivate the people. There is still a key role played by humans thanks to their experience, power of observation, communication and critical analysis.

Starting from the awareness that every terminal is unique, with its own mix of equipment, cargo, vessel types, labour relations and commercial agreements, the challenge for all terminals, regardless if they are fully-automated, semi-automated or manned operations, is to maximise productivity using standard solutions paying attention to operational systems configuration, training, process and people management, referring to actual cases and learned lessons.

In the case of solid organisation of experienced traditional RTG, SC or RS terminals, a structured optimisation project can boost terminal productivity: toanalyse the right indicators, review the business process, dive into the Terminal Operating System (TOS) logic and algorithms, can bring unexpected benefits and eliminate a lot of the guesswork within the organisation, and enable terminals to respond quickly to changes of operational and commercial conditions, without capital investments.

In few words: Make better use of what you have.

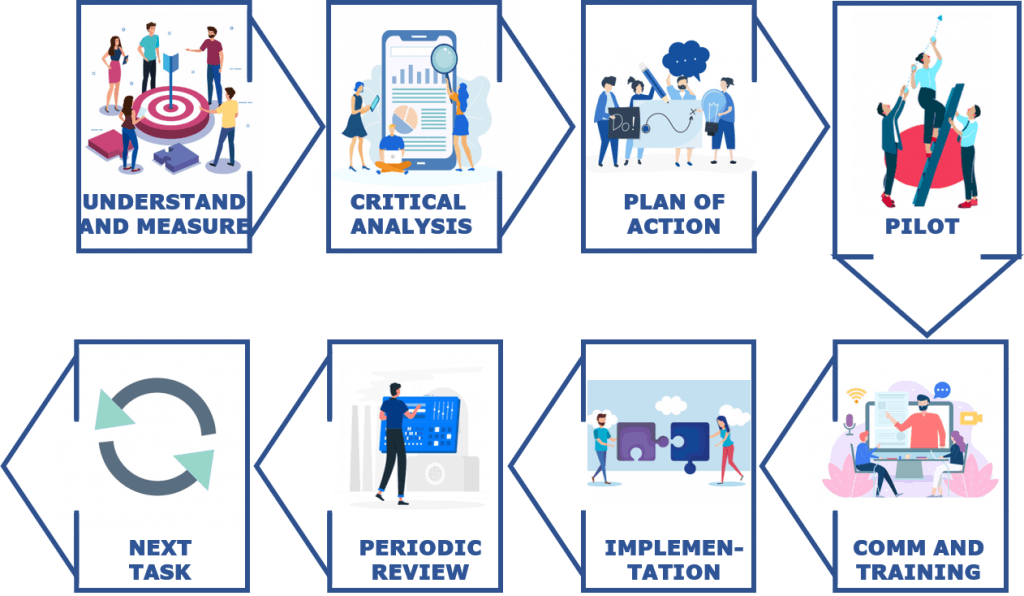

Methodology

A successful optimisation project, usually performed with the support of professional experts, can be designed and customised around a well-defined and structured loop schema.

On top of the implementation work itself, it is important that the optimisation project is sponsored by management and targets and objectives are shared among all stakeholders with a strong and formal blessing of management.

Understand and Measure

Regardless if the optimisation project is carried out by internal staff with the support of an external team, whoever approaches the optimisation project should in the first instance start with the “tabula rasa” or clean slate mind-set and review the process as if it’s new without prejudice and holds. This is where a young smart apprentice could bring value, as he may raise questions which are obvious for an experienced fox, but sometimes answers are not as easy and obvious as expected.

To understand the process through interviews, process observation and job shadowing should be reinforced by measurable values, KPIs to enlighten areas of attention and extremely important, to compare before and after and prove that improvement actions actually affecting the process and were correct: you must be able to show the effectiveness of your actions.

Critical Analysis

Once processes are clear and measurable, it is the time to search for the critical issues that prevent the terminal achieving the expected and desired objectives.

In this phase it is important to review the targets themselves as they could be misleading or contradict each other; in example a generic assumption like “reduce housekeeping moves” is not well structured to define an optimisation project. To reduce housekeeping is an action but not the target itself that could actually be to reduce night shifts, to reduce RTG hours, under the big umbrella of cost reduction.

Plan of Action, Priority, Risks and expected results

Once analysis is completed, the optimisation team shall draw a plan of action and identify which of them is returning the highest improvement compared to the effort you have to invest on.

Sometimes lean actions bring unexpected high value results, like sharing shift objectives to the workers before start, reorganise the shift change procedures, segregate import containers by bill of lading and agree night delivery with the forwarder to decongest the gate in peak hours.

In other situations, optimisation deals with TOS tuning and configuration, to avoid workarounds or to use modules that have been licenced but actually never used.

Pilot Implementation. Review and tuning

Once actions are agreed and well planned it’s time to test them, with the assistance and supervision of the appointed experts.

The pilot has the aim to verify the feasibility of the action or in absence of a simulator, to test the new TOS strategy in operations for a limited period and with immediate possibility to roll back, possibly stressing the new strategy against a single vessel, yard area.

Even if the pilot, depending on the action itself, could be limited it gives a good overview of possible tricks, tuning that shall be taken in consideration before actual go live of the new strategy.

Documentation, Communication and Training

Once the plan is clear, the commitment of all process stakeholders is critical for success. Everyone should be aware and competent for his part on the changes.

In any case, training or quick reference manuals shall be prepared.

The high risk of an optimisation project is that they rely too much on the project team, and once the team hands over to the end users the new process, even if it was highly performing during support period, this suddenly stops working and productivity drops. The optimisation is quickly abandoned in favour of a conservative and safe approach, that we could name the headache prevention.

Implementation and constant application

To take the solution in production is actually a go live, regardless if it’s a software module or a new working procedure and shall be managed accordingly, with a go live readiness, check list and proper support from the project team.

Handover shall take place when the new process is stable and when it is clear that the end users are trained, comfortable and willing to take the challenge.

Periodic review

Never abandon an optimisation action, it requires care and constant review. You never reach perfection and perfection itself is a moving concept, influenced by the environment and by the eyes of the observer himself.

Next Task

If you remember, the optimisation project was made up of a plan of actions, so let’s review again the condition now that the first action was completed and move to the next.

You get never bored by optimisation.